In the home improvement industry, product reliability and energy efficiency aren't just selling points – they're essential to safe, functional and enjoyable homes. And at the heart of maintaining these standards is product testing. At Guardian, we ensure our products are subject to both internal and independent testing, ensuring the quality and reliability of our systems. Gordan Lee, our Technical Engineer, discusses how we ensure our products remain energy efficient with accurate performance figures:

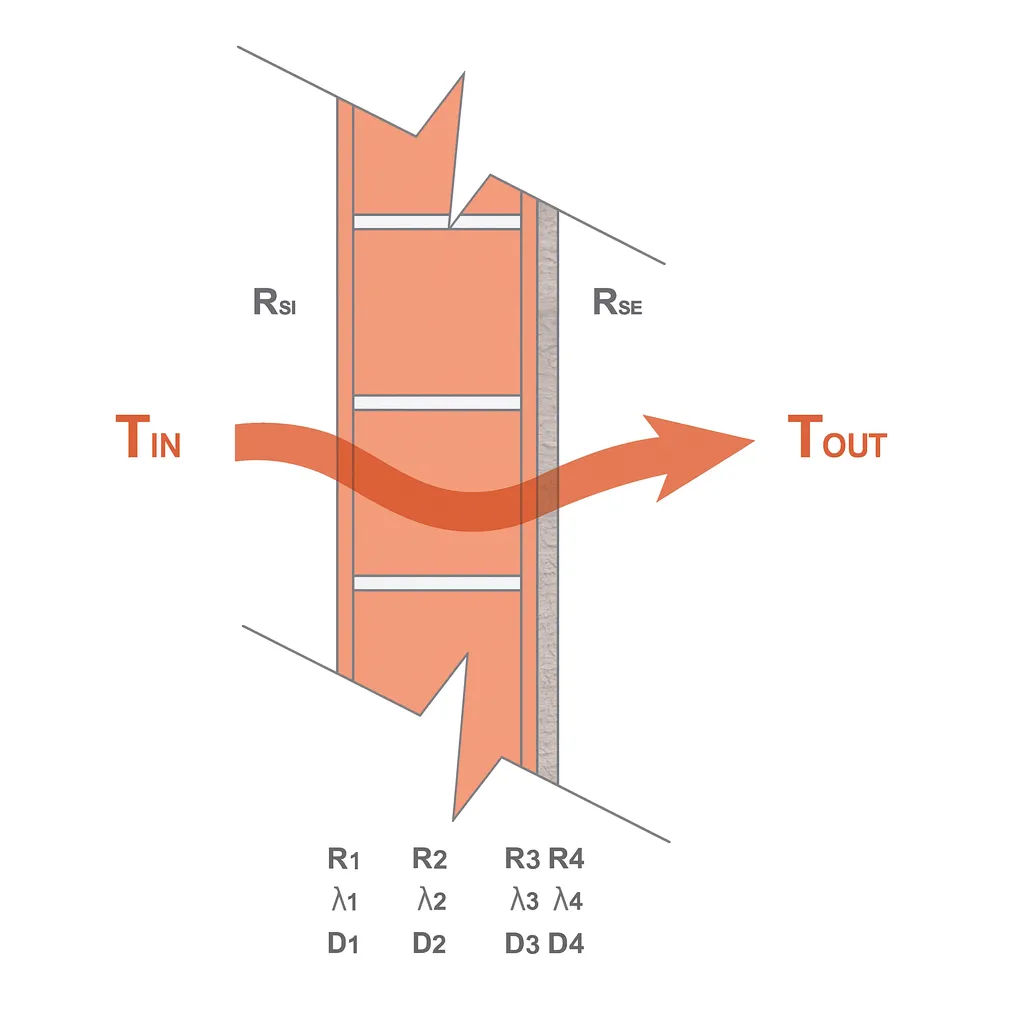

We carry out a wide range of tests on Guardian’s systems. A lot of the work lies in theoretical testing, including a lot of CAD work and 3D modelling. Recently, we’ve focused on thermal testing using the Trisco software package – the same software used by BRE. Trisco helps us calculate the U-value of a system’s cross section, which then informs the overall U-value. Our testing determines U-values for new systems as well as evaluating potential improvements to existing products. Currently we’re assessing the insulation in the Guardian Warm Roof to determine whether alternative materials could improve its thermal efficiency.

Even before we began using Trisco, we relied on independent testing, and we’ve maintained that commitment ever since. We always work with BRE, who in my opinion are the best independent testers out there, to confirm our results. You can do testing in-house, but we believe it is important to have products tested independently to ensure the results are accurate and backed up! Our design process prioritises energy efficiency, and when needed, we work with structural engineers and thermal experts. This dedication to such high standards is why Guardian remains a leader in the market.

Any product innovation starts with the concept designs. We always send out communications to the relevant team members and give everyone a chance to present a concept. We give everyone a chance to present a concept design and hold a kick off meeting to discuss these in more detail.

Once this is done and decisions are made, we then go through rigorous CAD processes where we will design a component based off the concepts agreed. We devise a stringent CAD test programme where we consider all interactions involving that component and note any issues. This is also where we will bring in thermal and structural engineers if necessary.

As soon as everything is approved, we have a physical testing process at our site in Ireland. Any issues are marked down, and once we’re confident in the design we send the components to BRE for independent testing. If the results meet their standards, then the product is ready for market. It definitely takes a while for the whole process to complete, and it can cost a lot of money too, but if you fail to complete these tests then it can have catastrophic consequences, so they are very important.

Our commitment to both internal and independent testing is the cornerstone of our success. Each Guardian system undergoes a rigorous process to ensure that what we are selling is exactly what you receive. As Gordon’s insights show, investing in high-quality testing ensures smarter decisions, stronger products, and long-term trust from our customers.

Follow us on social media to learn more about how we deliver ‘Performance U Can Rely On’!